In the realm of sustainable energy storage, deep-cycle batteries stand as the backbone for a multitude of applications ranging from renewable energy systems to electric vehicles. Among these, the flooded lead-acid deep-cycle battery remains a popular choice for its reliability, cost-effectiveness, and capacity for deep discharge. This article delves into the nuances of maintaining and optimising the performance of flooded deep cycle battery, shedding light on the art of prolonging their operational life.

The Significance Of Regular Maintenance

Ensuring the enduring functionality and efficacy of flooded lead-acid deep-cycle batteries hinges on committed adherence to a regime of regular maintenance. These types of batteries necessitate routine inspections to verify that electrolyte levels remain within optimal parameters and to ascertain that connections are both clean and secure, whilst also ensuring the integrity of the battery casing.

The omission of these critical maintenance activities can precipitate the onset of sulphation, a condition characterised by the crystallisation of lead sulphate on the battery plates, thereby degrading both capacity and operational lifespan. Furthermore, situating the battery in an environment that is consistently clean and devoid of extreme temperature variations plays a pivotal role in mitigating the risk of its premature degradation.

Such diligent maintenance not only fortifies the battery against common failings but also reinforces its ability to meet the rigorous demands placed upon it, thereby maximising its utility and longevity in a wide array of applications.

Optimal Charging Practices For Maximum Battery Life

The methodology adopted for charging flooded deep-cycle batteries exerts a profound influence on their health and operational longevity. An overzealous charging regimen can precipitate electrolyte depletion, heightened thermal conditions, and accelerated grid corrosion. Conversely, inadequate charging is known to catalyse sulphation. The deployment of a tripartite charging strategy—encompassing bulk, absorption, and float stages—promises to refine battery efficacy.

In the initial bulk phase, a constant current is delivered to the battery until it attains a specified voltage threshold. The subsequent absorption phase maintains this voltage, facilitating the battery’s approach to full capacity. The concluding float phase ensures the battery is kept at full charge through a reduced voltage, thereby curtailing the risk of overcharging.

Adherence to the charging guidelines prescribed by the manufacturer, coupled with the utilisation of a charger tailored for flooded deep-cycle batteries, is essential for extending the battery’s service life. This approach not only aligns with the best practices for battery maintenance but also underscores the significance of precision in the charging process to safeguard against premature degradation.

Flooded Lead Acid Deep Cycle Battery: Reliable Power For Demanding Applications

In the sphere of energy storage, flooded lead acid deep cycle battery has established themselves as a stalwart choice, particularly for applications that demand a reliable power source capable of enduring rigorous use. This type of battery is distinguished by its ability to provide a consistent and sustained power output over extended periods, making it an indispensable asset in environments where energy reliability is crucial. Flooded lead-acid deep cycle batteries find extensive application in areas such as renewable energy systems, where they are harnessed to store energy generated from solar panels or wind turbines.

Their capability to undergo numerous deep discharge cycles without significant deterioration in capacity or performance renders them ideal for such settings, where they effectively act as a buffer, ensuring a stable energy supply despite the intermittent nature of the energy sources. Moreover, these batteries play a pivotal role in the realm of uninterruptible power supplies (UPS), safeguarding critical systems against power disruptions. Their robustness and reliability are especially valued in industrial applications, where power continuity can be synonymous with safety and operational integrity.

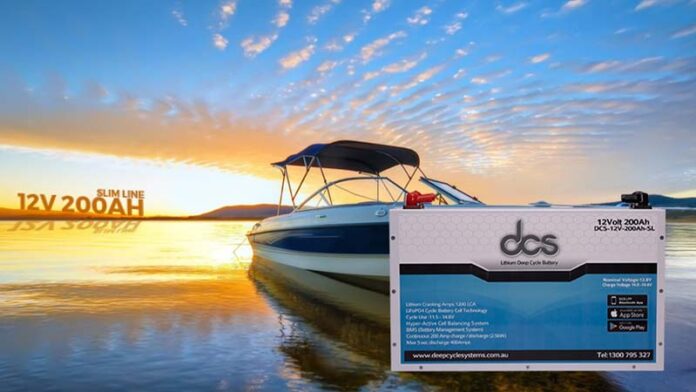

The versatility of flooded lead-acid deep cycle batteries extends to mobile applications as well, such as in electric vehicles (EVs) and marine vessels. In EVs, they provide the necessary stamina for extended travel ranges, while in marine contexts, they support a host of navigational and communication equipment, demonstrating their adaptability and reliability across diverse operational demands.

The Impact Of Temperature On Battery Performance And Lifespan

The influence of ambient temperature on the performance and lifespan of flooded deep-cycle batteries is a subject of significant importance in the maintenance and operational efficiency of these energy storage solutions. It is well understood within the energy sector that temperature variations can profoundly affect the chemical processes within these batteries, thereby impacting their overall functionality and durability.

At elevated temperatures, flooded deep-cycle batteries often exhibit enhanced electrochemical activity. This increased activity can lead to a more rapid charging process but concurrently accelerates the rate of water loss and the degradation of battery components, such as the lead plates and the electrolyte. Prolonged exposure to high temperatures not only diminishes the battery’s capacity more swiftly but also shortens its serviceable lifespan through the exacerbation of corrosion and other temperature-induced degradations.

Conversely, exposure to cold temperatures can significantly impede the battery’s ability to deliver its rated capacity. The chemical reactions responsible for generating electrical energy become less efficient in cold conditions, reducing the battery’s output and making it more challenging to meet the energy demands placed upon it. Furthermore, charging processes are also affected, requiring adjustments to charging rates to compensate for the reduced electrochemical activity.

Deep Cycle Battery Acid: Essential Information For Maintenance And Performanc

In the meticulous upkeep of deep cycle battery acid, the role of battery acid is undeniably crucial. This electrolyte, a dilute solution of sulphuric acid and water, facilitates the chemical reactions necessary for energy storage and release. Proper maintenance of the electrolyte level is essential; it must cover the lead plates to ensure efficient operation while avoiding overfilling, which can lead to acid spillage and consequential damage. The specific gravity of the electrolyte serves as a vital indicator of the battery’s state of charge and health, necessitating regular checks with a hydrometer.

Adjustments to the electrolyte, incorporating distilled water to compensate for evaporation losses, are imperative in maintaining optimal performance. Moreover, safety measures during handling, including wearing protective gear to prevent acid burns and ensuring adequate ventilation to dissipate harmful gases, are critical. Understanding and managing the nuances of battery acid in flooded lead-acid deep-cycle batteries thus forms a foundational pillar in their maintenance regime, pivotal in sustaining both performance and longevity.

Protecting Your Battery Against Corrosion And Over-Discharge

In the maintenance of flooded deep-cycle batteries, the prevention of terminal and connection corrosion emerges as a critical step. The accumulation of corrosion impedes electrical conductivity, thereby diminishing the battery’s efficiency and operational life. The application of a conservative layer of petroleum jelly to the terminals stands as a preventative measure, aiming to shield these critical points from corrosive agents. Concurrently, safeguarding the battery from instances of over-discharge is equally vital.

Subjecting the battery to discharge levels below the manufacturer-recommended threshold instigates irreversible harm, curtailing its operational lifespan. The integration of a low-voltage disconnect mechanism offers a proactive solution, automatically severing the load connection when the battery voltage falls below a specified limit, thereby preventing over-discharge and ensuring the preservation of the battery’s integrity. These strategies, centred around the mitigation of corrosion and over-discharge, play an instrumental role in extending the serviceable life of flooded deep-cycle batteries.

Optimizing Charging Practices For Maximum Battery Longevity

Optimising charging practices plays a crucial role in enhancing the longevity of flooded deep-cycle batteries. An approach that combines precision and attention to detail ensures that the batteries receive optimal charge without experiencing detrimental effects. Central to this process is the adherence to a charging protocol specifically designed for flooded deep-cycle batteries, one that incorporates the nuances of the battery’s chemistry and construction.

The implementation of a charging regimen that includes the stages of bulk, absorption, and float charging is fundamental. Each stage caters to a different aspect of the battery’s charging cycle, ensuring that it is efficiently brought to full capacity without overcharging or undercharging. For instance, during the bulk phase, the battery is charged at a constant high rate until it reaches a set voltage level, which is then reduced during the absorption phase to top off the battery’s charge without causing undue stress.

The implementation of a charging regimen that includes the stages of bulk, absorption, and float charging is fundamental. Each stage caters to a different aspect of the battery’s charging cycle, ensuring that it is efficiently brought to full capacity without overcharging or undercharging. For instance, during the bulk phase, the battery is charged at a constant high rate until it reaches a set voltage level, which is then reduced during the absorption phase to top off the battery’s charge without causing undue stress.

The float stage maintains the battery at an optimal charge level, significantly reducing the risk of degradation over time. Moreover, the significance of temperature compensation in the charging process cannot be overstated. As ambient temperature affects battery performance, adjusting the charging voltage in response to temperature fluctuations ensures that the battery is neither overcharged in hot conditions nor undercharged in cold conditions.

Flooded Cell Deep Cycle Battery: Reliable Power Solutions For Various Applications

Flooded cell deep cycle battery, with their robust design and dependable performance, have carved a niche for themselves across a spectrum of applications where reliable power is a critical requisite. These batteries are notably utilised in renewable energy systems, such as solar and wind power installations, where their ability to undergo deep discharge cycles without significant degradation is invaluable. The capacity of these batteries to retain charge over extended periods makes them an ideal choice for off-grid energy solutions, ensuring that power is available when needed.

In the realm of marine applications, flooded cell deep cycle batteries are favoured for their endurance and reliability. The power a variety of equipment on board, from navigational devices to propulsion systems, demonstrating their versatility in meeting the demands of marine environments. Their durability is particularly appreciated in situations where consistent power supply is crucial to safety and operational efficiency.

Recreational vehicles (RVs) also benefit from the robust energy storage solutions provided by flooded cell deep cycle batteries. These batteries support the electrical needs of RVs, from lighting to appliances, facilitating comfort and convenience on the move. Their ability to provide sustained power makes them an essential component in the design of modern RVs, catering to the lifestyle of enthusiasts who seek adventure without sacrificing the amenities of home.

Monitoring And Testing Your Battery’s Health Regularly

The vigilance in observing and evaluating the condition of flooded deep-cycle batteries through regular monitoring and testing is an essential practice for sustaining their health and functionality. Such diligence involves conducting routine checks of voltage levels and the specific gravity of the electrolyte, using tools like multimeters and hydrometers. These measurements are invaluable in deducing the state of charge and overall health of the battery. Furthermore, the application of load testing emerges as a crucial method to ascertain the battery’s capability to handle its expected operational demands.

Engaging in such practices on a scheduled basis enables the early detection of potential issues, facilitating interventions that can preclude the progression to critical failure. This regimented approach to battery care ensures that any deviation from normal operational parameters is promptly identified and addressed, thus maintaining the battery’s efficacy and extending its serviceable lifespan. Importantly, while incorporating these monitoring and testing protocols, it is imperative to adhere to the safety guidelines provided by the battery manufacturer to prevent accidents or damage to the battery.

FAQs

What Is The Ideal Frequency For Checking Electrolyte Levels In Flooded Deep Cycle Battery?

It is recommended to inspect the electrolyte levels in flooded deep cycle battery at least once a month. This ensures that the electrolyte covers the lead plates adequately, facilitating optimal chemical reactions for energy storage and release. Regular inspections help in maintaining the battery’s efficiency and longevity.

How Does One Accurately Measure The Specific Gravity Of The Electrolyte?

Utilising a hydrometer, one can gauge the specific gravity of the electrolyte, which provides insights into the battery’s state of charge and health. It is crucial to ensure that the electrolyte is at the correct level before taking a measurement, adding distilled water if necessary to compensate for evaporation losses.

Can Flooded Deep Cycle Batteries Be Used In Any Orientation?

These batteries are designed to be used in a specific orientation, typically upright, to prevent the leakage of electrolyte and ensure proper functioning. Deviating from the manufacturer’s recommendations can lead to damage and diminished performance.

What Are The Safety Precautions To Observe When Handling Flooded Deep Cycle Batteries?

When dealing with these batteries, wearing protective gear, such as gloves and goggles, is essential to prevent acid burns. Additionally, working in a well-ventilated area is recommended to dissipate harmful gases released during charging.

How Does Temperature Affect The Charging Process Of Flooded Deep Cycle Batteries?

Ambient temperature plays a significant role in the charging process, with elevated temperatures necessitating adjustments in the charging voltage to prevent overcharging. It is advisable to refer to the manufacturer’s guidelines for specific temperature compensation values.

Conclusion

In summarising the discourse on extending the lifespan and enhancing the efficiency of flooded deep cycle battery, it is evident that the intersection of diligent maintenance, precise charging practices, and astute operational management forms the bedrock of achieving prolonged battery service life. The comprehensive exploration of these facets underscores the necessity of a holistic approach that intertwines regular inspections, temperature regulation, and the avoidance of over-discharge and sulphation.

| Related Business Listings |

| Contact Directory |

| Local Business Profiles |